|

|

|

|

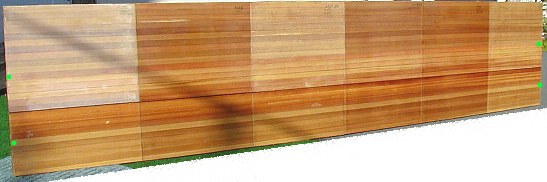

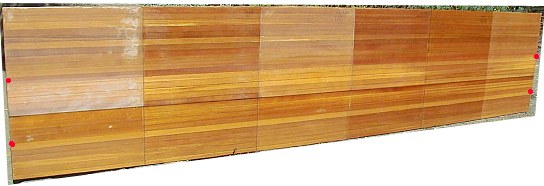

| This is what the panel looked like when it was new. The panel below reflects changes after two months outside. The third panel shows the epoxy after six month of continuous exposure to the elements. | |

Panel at 6 months (compare the light band in the middle)

|

I have omitted the close-ups of the individual epoxies because the changes are too subtle to be picked up by the camera at this distance and displayed visibly at 72 dpi (dots per inch) monitor resolution. The plastic 'light shield' covered the middle band between the red dots at the edges of the photo. |

|

|

|

|

| Fabric

'whitening' - It was clear from the two month test

that fibers coated with a thin layer of epoxy showed signs of discoloration.

The thin epoxy coat has now succumbed to oxidation particularly on the blushing

epoxies such as the WS206 and the EastSys. Patches of the WS206 are severely

eroded from water penetrating into the fibers which caused complete delamination

of the 'filler' layer of epoxy. It is interesting to note that the WS206

is supposedly more water resistant than the WS207 but it just doesn't stand

up well to UV radiation. The whitening of the fibers on the other samples

has stabilized and is not much worse than it was four months ago. Erosion of WS206 below:  click

on image for magnification click

on image for magnification |

|

|

Color changes and

surface oxidation- |

|

| . |

Epoxy shrinkage

- All epoxies show substantial shrinkage and fabric print-through. Here

is an example of Raka print-through. |

|

Varnish 'water resistance'

- The varnish is holding up really well and I can't discern much change

except a slight "loss of gloss". |

|

|

|

| Home | Kayak Designs | Kayak Shop | Materials | Kayak Gallery | About us |

| Building Manual | Plans | Sandwich Core | Wood Kayak | Order | |

| Epoxy Test | Abrasion Cloth | Rudder | Resources | Choosing Kayak | Guestbook |

If you notice any problems with the site (i.e. error links, missing images) please, let me know. Thanks

Mail:

Vaclav Stejskal

10 Colonial Court apt. 73

Stoneham, MA. 02180

USA

Tel: 781-481-9261

© 1999

- 2020 Copyright Vaclav Stejskal

All rights reserved

Last page update:

11 January 2020