|

||||

| INDEX | next

|

|

There

are two ways to smooth the surface in preparation for fiberglassing. The

ridges between the strips can either be planed or beltsanded. Both methods

have their pro's and con's. I used to plane everything initially but found out that 50grit beltsanding produces uniform finish much faster than any plane. It may sound more dangerous but it is not so. This type of sanding is done only to knock down only the grossest roughness anyway. If you want a mirror-like surface on your kayak, the rest must be done with the fairing board. |

|

Here,

the Cape Ann Expedition gets the 'plane'

treatment after some spot-filling. While beltsanding is faster AND doesn't

discriminate between hardwood or softwood the plane does shave the pores

left by the staples very cleanly, so the filler penetrates deeper into the

wood. The first filler round is mainly devoted to filling colored wood with oil based filler which stains the surrounding wood and is hard to sand out. The major staple hole filling with water based filler happens next. |

|

This

photo shows smoothing work on the inside of the kayak. Of all tools I have

tried, a humble paint scraper gives the best results especially in the tight

curves of the chines. The shape of the blade and a special technique turn

it into a superb spokeshave. Trying to use it like a traditional paint scraper

doesn't work! Note the long curly shavings made by it. The next best tool is a 7" coarse sanding disk on a drill. Working with planes on the inside is too inefficient (even with a rounded base). |

|

All

filling of gaps and staple holes is done right after coarse sanding (planing)

but prior to the fairing board. Waiting to fill everything until the fairing board job is done would require more sanding anyway. This time, however, the temptation is to remove only the filler smudges at the stations. What you don't see are the hollows that your sander is making right under your nose. The varnish will reveal a nicely rippled and uneven surface. With that said again: fill gaps and staple holes as early as you can! |

|

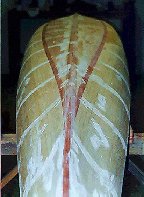

The bow of the Expedition. The dark Western Red cedar and Redwood were filled carefully so that the filler would not contaminate the pine and the light wood. |

|

Water based fillers are the most forgiving of mistakes and can be used right up to the fiberglass work. Oil based fillers are OK but must be used early on so as not to leave oily stains (thin with acetone). Epoxy fillers are the worst by far. If you want to use epoxy putty you might as well seal the entire surface first with epoxy, then use the putty, and then sand the whole thing before glassing. It is simply too much work for little return. A water-based three component mix (photo) (Durham Water putty, WS110-phenolic microballoons, wood dust) The whitish haze left after this filler completely disappears under the epoxy resin. Most other fillers are NOT that forgiving and you will have to sand the stuff out of the wood. Both Oil based fillers as well as epoxy filler, will leave a distinct spot of different hue if left on. |

|

.Ready

for fiberglass.

|

| INDEX |

| Home | Kayak Designs | Kayak Shop | Materials | Kayak Gallery | About us |

| Building Manual | Plans | Sandwich Core | Wood Kayak | Order | |

| Epoxy Test | Abrasion Cloth | Rudder | Resources | Choosing Kayak | Guestbook |

If you notice any problems with the site (i.e. error links, missing images) please, let me know. Thanks

Mail:

Vaclav Stejskal

10 Colonial Court apt. 73

Stoneham, MA. 02180

USA

Tel: 781-481-9261

© 1999

- 2020 Copyright Vaclav Stejskal

All rights reserved

Last page update:

11 January 2020