|

||||

| INDEX | next

|

|

View from the other

direction. Note the chair supporting this |

|

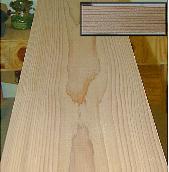

The ideal board of cedar

for making strips. |

| INDEX |

| Home | Kayak Designs | Kayak Shop | Materials | Kayak Gallery | About us |

| Building Manual | Plans | Sandwich Core | Wood Kayak | Order | |

| Epoxy Test | Abrasion Cloth | Rudder | Resources | Choosing Kayak | Guestbook |

If you notice any problems with the site (i.e. error links, missing images) please, let me know. Thanks

Mail:

Vaclav Stejskal

58 Wood Ln.

Acton, MA 01720

USA

Tel: 781-481-9261

© 1999

- 2024 Copyright Vaclav Stejskal

All rights reserved

Last page update:

9 May 2024