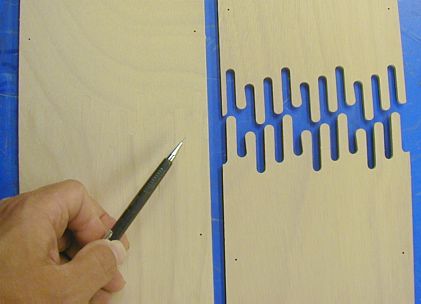

Exclusive self locking method of joining kayak plywood plates featuring super fast assembly, seamless visual blending and excellent mechanical strength.

Advantages:

1) Camouflaged joint: ScarfLOCK joint has an irregular serpentine shape with long period of repeatability so that it blends nicely with the natural growth rings pattern on plywood and you will barely see it on your kayak - the ultimate joint camouflage. There is no line intersection perpendicular to the direction of the plywood fibers or a regular repeating "wave" of shallow fingers like on other kit scarfs.

2) Good color match across joint line: Everyone knows that wood comes in many different shades of color and scarfing one kayak plate from different sheets of plywood accentuates the joint rather than hiding it. One Ocean Kayaks plates are cut so that adjoining ends are right next to each other when possible on the same sheet of plywood which assures the best color and grain match across the ScarfLOCK.

3) Positive locating and Self aligning: You don't need to second guess what ends of the plates join together. ScarfLOCK is unique to every plate joint like a lock and its key. Once the fingers are engaged, the plywood sections are aligned. This is not possible with a traditional scarf joint or even non locking finger joints made by other kayak kit manufacturers.

4) Self locking. ScarfLOCK features "key fingers" that interlock into each other like a puzzle. Once snapped together, the ScarfLock cannot pull apart, even unglued!

5) Strength with large glue surface area. The strength of the joint is directly proportional to the glue area, and also to the angle of the glue line/surface in relation to the direction of anticipated principal stresses (along fiber direction). The more collinear the glue line the stronger the joint, conversely the more perpendicular the glue line, as in a butt joint the weaker the joint. The ScarfLOCK has both the highest glue area and collinearity of all other "finger joints" used in kayak hulls or boatbuilding in general. For every inch of plate width, the ScarfLOCK glue joint is almost 5" long!

6) Stress distribution. Unlike other finger joints, ScarfLOCK fingers are staggered in a Zig-Zag fashion to eliminate the "stress concentration" line along which other finger joints fail prematurely.

7) Precision. ScarfLOCK is made on CNC machinery capable of repeatable precision of 0.0005"/30cm (0.0127mm) which is five times thinner than a human hair. Virtually all other kits made on CNC machines go only to 0.005" (10 times less accurate) which is NOT accurate enough to make One Ocean Kayaks ScarfLOCK - it would be either too sloppy or not fit together! The slip fit gap between the fingers on ScarfLOCK is measured on the order of 0.001" so a hair will not fit into the joint.

8) Speed of assembly and fast kayak building. After you apply wood glue to the ScarfLOCK, the fingers will swell a small amount and the resulting press fit allows the plate to be manipulated immediately and used in the kayak in about an hour. The entire set of plates for the Cirrus take about 2 hours to "ScarfLOCK" together. Ask other kit manufacturers if you can start building their yaks the same day you receive the kit.

See the ScarfLOCK joining process.

Disadvantages: None I can think of. Only for the competition ;)